direct drive vs belt drive motor

Answer 1 of 27. Direct Drive Fans Arrangements 4 7 and 8 are the most common direct drive fan configurations.

Home Compressor Motor Motor Laundry Direct Drive Bldc

According to different transmission parts CNC vertical machine center pindles are divided into four types.

. Direct drive motors sometimes called pancake motors are synchronous motors which operate by variable speed 3-phase AC. Belt drive elastic can wear down and it can eventually break. Belt drives apply greater load on the main shaft of the machine it has a direct effect on the life time of bearings shaft misalignment and as a result oil leakage and more vibrations.

The Direct Drive Turntable. Belt-drive turntables by contrast usually take several seconds to get up to speed. The motor is directly mounted underneath the washing machine drum.

This situation is obviously very rare. A direct drive turntable features quick start-up times slightly more consistent speed and stronger torque. Direct drive system usually uses brushless motors that do not make more noise.

The next easiest options are belt drive or a geared stepper motor. Arrangements 7 and 8 use the fan shaft and bearing design found on belt drive fans except instead of connecting the motor to the fan shaft via a belt drive the fan. Browse discover thousands of brands.

The two types of motors a table saw can use are belt driven and direct driven. Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. Assuming speed reduction a direct drive low speed motor will have a lower efficiency lower power factor bigger size and higher cost as compared to belt driven higher speed motor.

Another drive way is belt driven which allows the rotating speed of the rotor to be changed by pulleys of different diameters. On the other hand belts tend to break every so often meaning that you tend to perform more repairs. Therefore it is a wrong view that there is no energy loss in direct drive.

The belt driven system. Belt-driven motors are traditionally more cost-effective but they require moving parts to be lubricated often which may lead to more maintenance costs. A direct drive system simply makes these changes and.

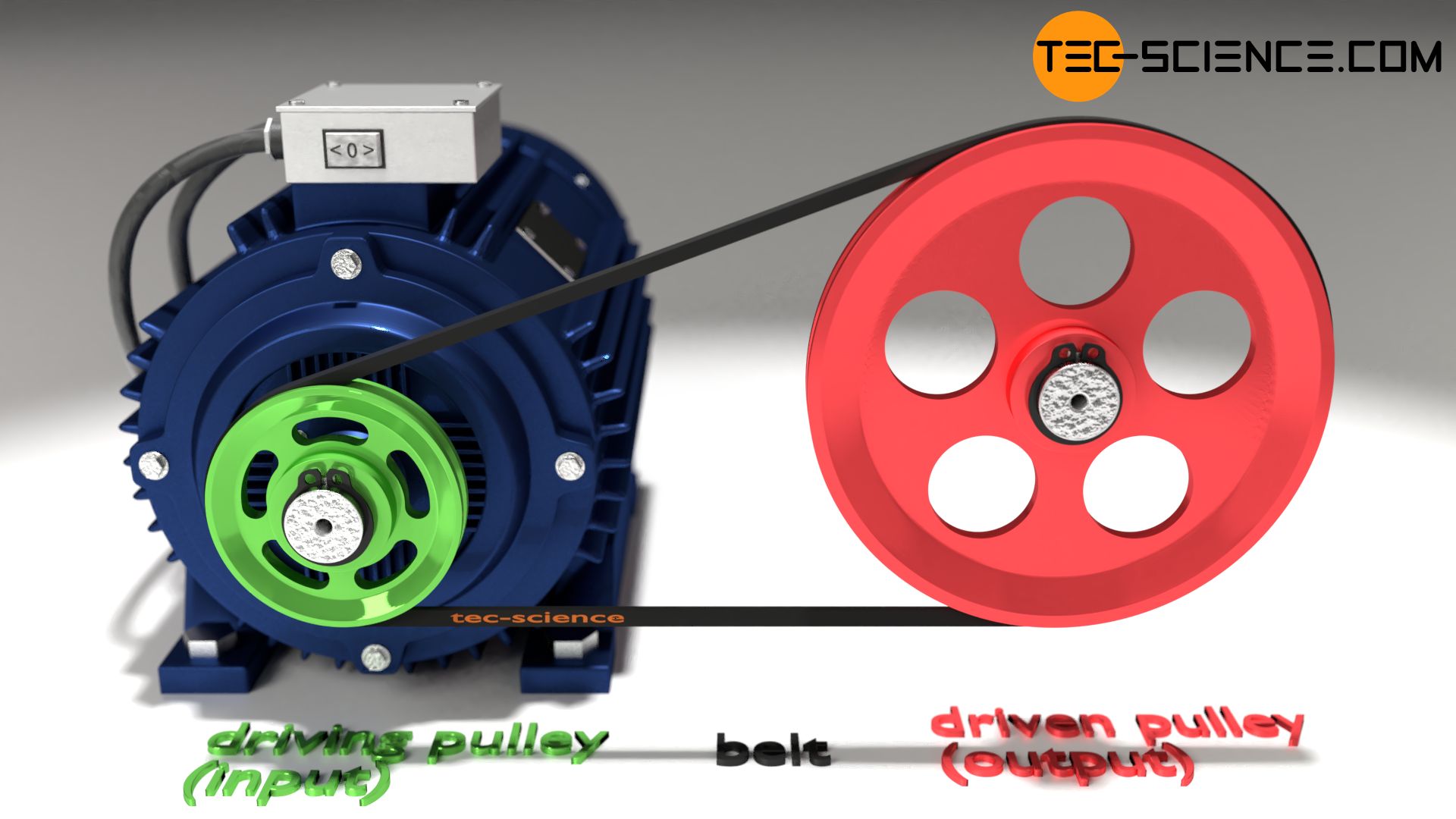

As you might have guessed the primary difference between a direct drive motor and a belt drive motor is that the former does not utilize a belt. Greater efficiency is the biggest pro of direct drive fan configurations. Even when belts are properly tensioned and the sheaves are aligned the power transmission loss of a belt drive fan.

In summary price and the fact that belt drive motors are not attached directly to the turntable are the two biggest differences. However the bearings and other. They also dont tend to have as many features as direct drive motors.

Of course belts themselves have plus. Check what the Magnetic Innovations team can do for you. As further security against unwanted sounds the best manufacturers suspend the motor.

Would I be able to run the drivers at a lower power setting if I used gearing. Theres also no belt residue and these fans cost less to maintain generally speaking because belts dont wear down and break. In a force feedback system rapid motor direction changes are common.

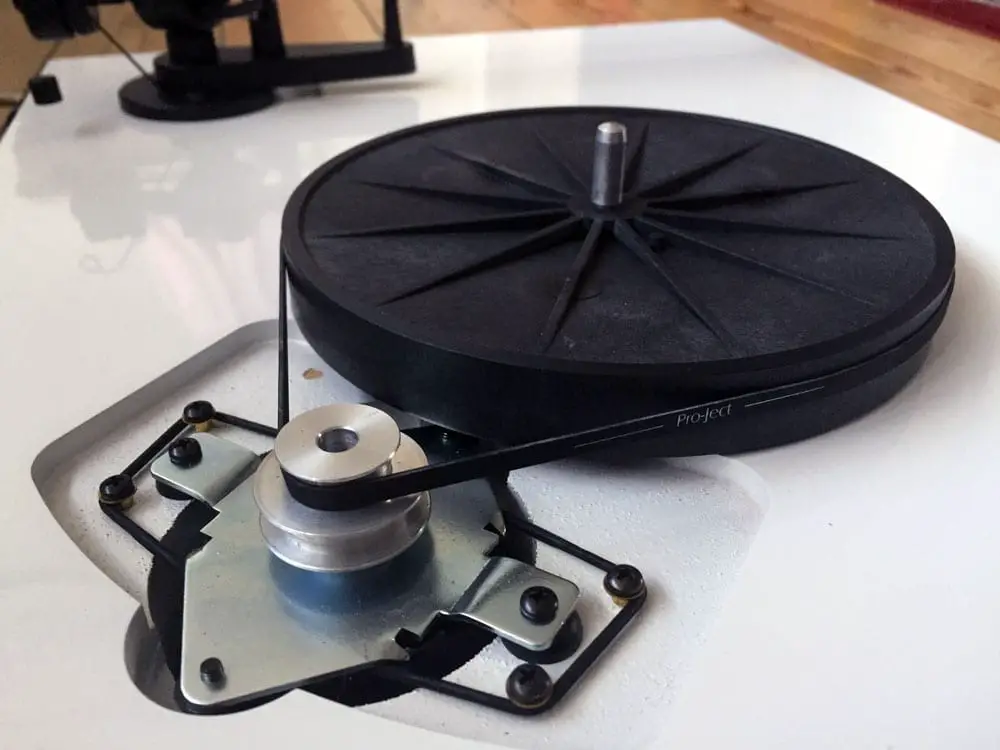

The direct drive turntable meanwhile features a platter which is directly attached to the players motor. Video of the machine running. Also they do not have as much longevity as direct drive motors.

Would a geared or belt drive help reduce the vibration in the mechanism. Gear drive spindles belt drive spindles direct drive spindles and electric spindles. The obvious advantage of direct drive is simplicity.

The difference between belt drive and direct drive of VMC. Lesson Direct is Your Online Solution For Electric Motors Controls. Additionally theyre easier to clean.

The motor is the spindle and the spindle is the motor. Given that direct-drive engines are the newest technology they tend to have more features. Ad More than 40 Frameless High Torque Rotary Motors tailored to your needs.

A belt drive will isolate the sound of the motor from the platter. This kind of pump mounts directly on the motor or engine has few moving parts and is the most cost-effective option. The motor is placed away to one side and the only thing that touches the platter is the rubber belt.

Direct-drive tables also will give you a speed control so as a DJ if you want to change the tempo to blend one song into another with two turntables it is pretty easy to do so with the range of speed adjustment available on a direct-drive table. The stator contains the 3-phase windings and the rotor contains. Direct drives requires less space in comparison to belt drives so smaller machines.

Ad Leeson Electric Motors Drives Controls. Direct drive motors are far more efficient than an equivalent belt drive motor. The motor and the spindle are.

This is the Arduino Code. Direct-driven motors dont require any lubrication and typically last longer but theyre usually more expensive. Read customer reviews find best sellers.

The belt drive motor would have to spin 20 times faster than the direct drive motor to match the direct drive systems ability to produce detail. No more power loss as the motor shaft is directly connected to the drum shaft. Unlike belt driven fans theres less energy loss because theres a reduced amount of friction as the fan operates.

It is therefore not even in direct contact with the turntable. Direct drive pumps are mechanically simpler than belt drive pumps. Direct drive pump.

Due to the simplicity of direct drive pumps the design is more compact which is useful when used in tight areas. Arrangement 4 is the most compact footprint with the motor installed directly onto the fan pedestal. Direct drive in the true sense means that the motor is directly connected with the rotor Coaxial which has the same speed.

However a belt drive fan has power transmission loss due to the friction between the belt and sheaves and due to the drive shaft bearings. The direct drive system eliminates the belt from the drive system. The second most distinct difference between the two is price.

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

Direct Drive Vs Belt Drive Turntable Which Is Better For Turntables

Direct Drive Vs Belt Drive Turntables What S The Difference Sound Matters

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

How Does A Belt Drive Work Tec Science

Chain Drive Vs Belt Drive Vs Shaft Drive Motorcycle Drivetrain Explained

The System Benefits Of Direct Drive The Comparison Tab Tv

Direct Drive Vs Belt Drive Washing Machines Which Is Better Survival Freedom

Direct Drive Motor Washing Machine Pros And Cons

Belt Drive Vs Direct Drive Laundry Youtube

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy

What S The Difference Between A Hub Drive And A Belt Drive Electric Sk Electric Board Co

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

What Is Better Direct Drive Motors Or Belt Drive Motors In A Washing Machine Quora

Home Compressor Motor Motor Laundry Direct Drive Bldc

Difference Between Direct Drive And Belt Drive Washing Machine Youtube

Sears And Whirlpool Direct Drive Washer Info The Appliance Clinic

Direct Drive Vs Belt Vs Gear Racing Wheels Which Should You Buy